VEGAPRESS

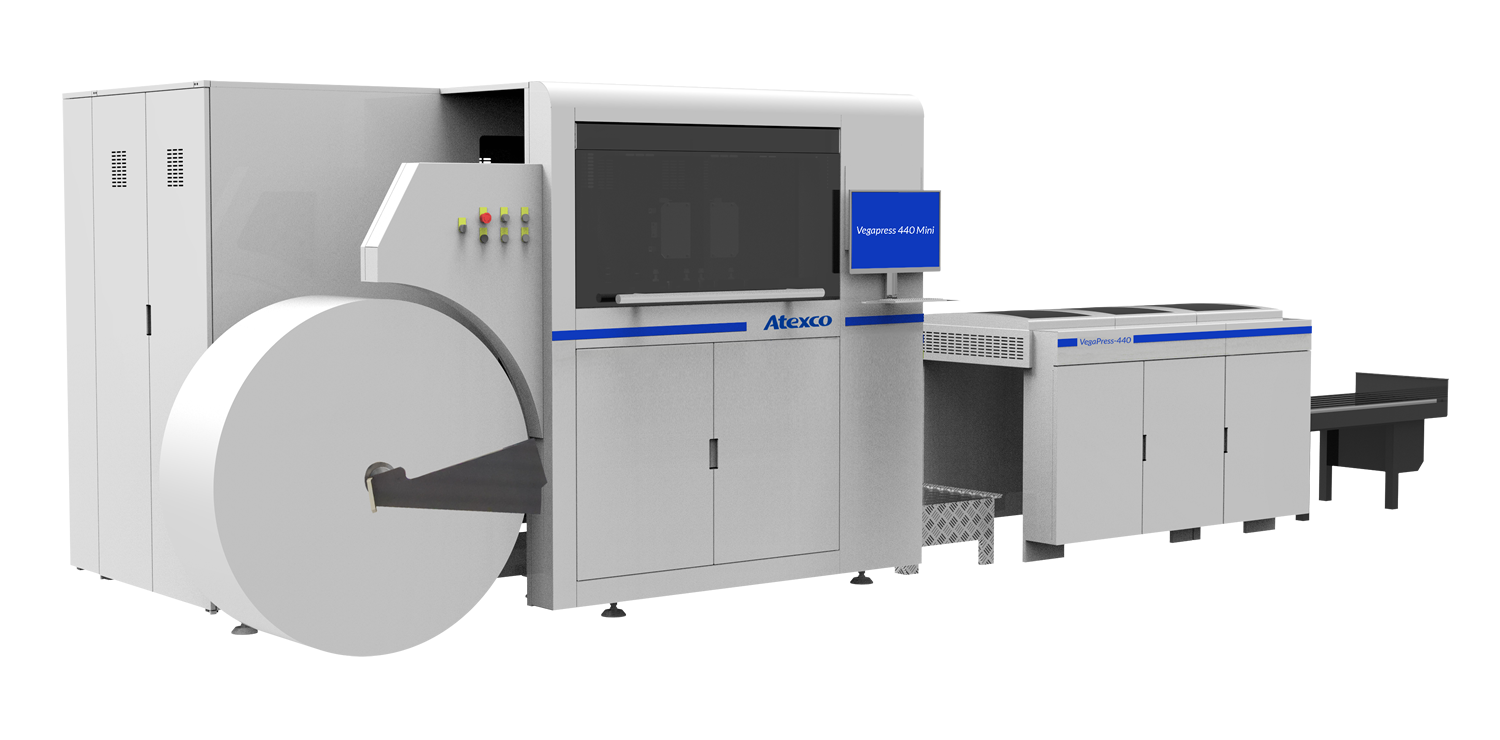

High-speed digital rotary inkjet

printing machines

660/440 M HD

Vegapress

Branded Digital Printing Machine Atexco

Vegapress is a powerful tool for the production of printed materials in publishing houses, government agencies, manual production companies, monochrome books, textbooks, school books, user manuals, instructions, vouchers, comics, and other industries.

Vegapress is a high-speed, high-quality monochrome rotary digital printing line supplied in different line, format and speed configurations (up to 150m/min). Capable of printing on offset uncoated paper from 40 gm2 to 200 gm2, it has the advantages of high print quality, large production capacity and low cost.

In just 10 meters it is capable of printing, cutting and collecting and delivering a book block.

Max. speed:

- 3,000 A4 pages per minute

- 20,000 sheets 64X44 cm per hour printed on both sides and collected

- 150 m/min

HIGH QUALITY AT LOW COST

Remote assistance: The machine is in constant connection with both the parent company and our offices in Padua and Milan. Thanks to the remote module developed internally by the manufacturer, the latter can provide users with software update services, real-time problem solving, guidance on the maintenance process and training on the operating process.

On-site assistance: technical personnel under direct control have been trained to intervene quickly, from the Padua and Milan offices, for any mechanical, electronic and software needs. The costs are the regular market rates for on-call intervention. Without the need for any monthly contract or click cost. Our policy is based on six-monthly preventive assistance and timely and efficient corrective maintenance when necessary.

Spare parts and their supply: The machine is built with widely consumed industrial components characterized by quality, reliability and high availability, such as Siemens, Schneider, Yakagawa, etc..

This peculiarity allows the customer to choose whether to purchase the components from our warehouse or from the closest and cheapest one to their production site. No block or code will limit the use of the same components purchased on the free market.

Training: Your operators will be trained to have a high level of intervention on the machine so as to significantly reduce calls from an external technician and unnecessary machine downtime.

|

|

|

The machine manufacturer, Hangzhou Honghua Digital Technology Co Ltd, has an ink manufacturing company in Germany and an ink manufacturing company in Tianjin, China, with a production capacity of 10,000 tons of digital ink per year. With these latest acquisitions, Atexco is the only machine manufacturer that can supply its own ink, eliminating many costs and intermediaries.

The machine manufacturer, Hangzhou Honghua Digital Technology Co Ltd, has an ink manufacturing company in Germany and an ink manufacturing company in Tianjin, China, with a production capacity of 10,000 tons of digital ink per year. With these latest acquisitions, Atexco is the only machine manufacturer that can supply its own ink, eliminating many costs and intermediaries.

The R&D team, including one in Osaka, Japan, independently develops special inks for high-speed inkjet machines, based on the characteristics of the paper, the high-speed and drying characteristics of the equipment, and the print quality requirements of customers. These inks have excellent inking properties, color saturation, and drying performance, and can be adapted to a wider range of papers.

Automatic unwinder: |

|

Digital printing unit: |

|

Buffer: |

|

Cutter – Stacking: |

|

Inks: |

|

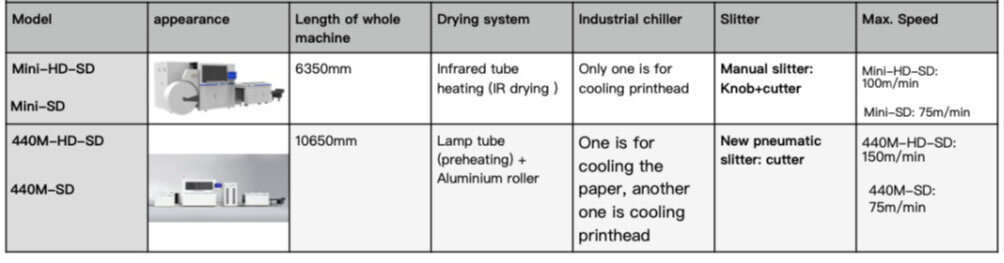

MINI SD

Vegapress

Atexco brand digital printing machine Atexco

MINI is the GREAT result of an engineering exercise capable of providing high production capacity in small dimensions. In fact, it encloses in just 6.77 meters the capacity to print, cut and collect at a speed of 1000 A4 pages per minute.

MINI is a high-speed and high-quality digital rotary inkjet printing machine, monochrome printing, double-sided in a single pass and collected sheet output.

Capable of printing on offset uncoated paper from 40gm2 to 200 gm2, it is ideal for printing monochrome books, textbooks, school books, user manuals, instructions, vouchers, comics, etc.

Max speed:

- 1010 A4 pages per minute

- 27,000 64X44 cm sheets per hour printed on both sides and collected

- 75 m/min

HIGH QUALITY AT LOW COST

Remote support: The machine is constantly connected to both the manufacturer and our offices in Padua and Milan. Thanks to the remote module developed internally by the manufacturer, users can receive software updates, real-time troubleshooting, maintenance guidance, and operational process training.

On-site support: Technical personnel directly employed have been trained to promptly respond from the Padua and Milan offices to any mechanical, electronic, or software-related needs. Costs are based on standard market rates for on-call interventions. No need for monthly contracts or click-based charges.

Spare parts and their supply: The machine is built using widely available industrial components known for their quality, reliability, and high availability, such as Siemens, Schneider, Yakagawa, etc.

This feature allows the customer to choose whether to purchase components from our warehouse or from the closest and most cost-effective supplier near their production site. No lockouts or codes will restrict the use of the same components purchased on the open market.

Training: Your operators will be trained to handle the machine at a high level of autonomy, significantly reducing the need for external technical assistance and unnecessary machine downtime.

|

|

|

The machine manufacturer, Hangzhou Honghua Digital Technology Co Ltd, has an ink manufacturing company in Germany and an ink manufacturing company in Tianjin, China, with a production capacity of 10,000 tons of digital ink per year. With these latest acquisitions, Atexco is the only machine manufacturer that can supply its own ink, eliminating many costs and intermediaries.

The R&D team, including one in Osaka, Japan, independently develops special inks for high-speed inkjet machines, based on the characteristics of the paper, the high-speed and drying characteristics of the equipment, and the print quality requirements of customers. These inks have excellent inking properties, color saturation, and drying performance, and can be adapted to a wider range of papers.

|

Automatic unwinder: |

|

|

Digital printing unit: |

|

|

Buffer: |

|

|

Cutter – Stacking: |

|

|

Inks: |

|

FAQ

The Chinese market has had a strong expansion in the digital sector.

….. ”from 41 in 2015 to 823 in 2021 and is rising at an increasing rate of 300 units per year confirmed in 2022, 2023 and 2024”

Source: Webinar between the main Chinese machinery manufacturers.

The market share is divided between 3 main players. Among these, Atexco is the only company with 30 years of history and with strong experience and a dedicated structure in the installation and assistance of its machinery overseas, boasting over 2000 active customers beyond the domestic market.

The history of Hangzhou Honghua Digital Technology, known as “Atexco” begins in Hangzhou in 1992 as a software house. Today it is a world-leading manufacturer of very high-speed digital printing machines, capable of proposing itself as a manufacturer and sole interlocutor for inks, software and digital printing machines for both the textile and paper markets. The recent listing on the stock exchange has allowed it to expand its product portfolio and build the most innovative factory for the production of digital machinery. In fact, the company has recently completed its new "smart factory" built in an area of approximately 260,000 square meters, which makes it the most innovative industrial hub for the production of digital machinery in China.

In numbers:

Over 2000 customers worldwide

Leading company with over 30% market share in the textile market

Over 500 employees

Over 260,000 square meters of production area

Listed in the domestic market

Two owned ink production companies

1000 tons of ink produced in Tianjin factory alone

Machinery certified by TUV Germany

Atexco Smart Factory

- 260,000 square meters of area

- 1.2 billion CNY invested, 155 million EU

- Haas CNC machines, from the USA

- High beam horizontal machining center

- Fanuc automatic welding robots

- S-axis gantry milling center

- Automatic tube cutting and drilling center

- RAS multi-bending center, fully automatic and perfect sharpening

- Bystronic laser cutting machine, from Switzerland

- Fully automatic painting line with drying system

- Production capacity of the entire plant 3000 sets per year

- VegaPress series capacity 250 sets per year

Advantages of the Atexco smart factory:

- Production of the machines entirely in its own plant

- Technical office of the main supplier, Kyosera, within the same building

- Proprietary machine management software. Maximum availability in the integration with other software for the management flow

- Ink of own production

- All-in-one digital solution, from the reel to the book block. The machine is composed of unwinder - printing tower - (Mono tower-1; CMYK towers-2 towers) - buffer (paper magazine) - cutting unit - book block square collection system or rewinder.

- The cutting and collection unit has automatic format change and the collection of sheets creates a homogeneous and staggered stack when creating each book block. This facilitates the collection of the book block for subsequent processing. In fact, from the machine output, the resulting book block can be sent directly to the trim cutting or binding. This system shortens the production processes and allows you to save significant investments in packaging equipment.

- Personnel: no special skills are required. For two machines, it is possible to use 1 worker thanks to the high level of automation and the intuitive interface

Increased productivity (high speed). Its production speed can reach max. 150 m/min for both 440/660 models

- NO CLICK! Cost of consumables, maintenance and operation lower than all the players in the sector. The ink is produced and sold by the same company without intermediaries. The water-based pigmented ink is not only more environmentally friendly than toner or other inks, it is also cheaper to produce. The machine is built with widely used industrial materials (Siemens, Schneider, Inovance, etc.). Consequently, the materials are tested by several industries, are stable, are available from the main electronics distributors, and have a low cost among spare parts dealers.

Request

information

Response within 24 hours

Enrico Camporese

+39 349 4340330