MORE THAN 60 CAMPORESE LED-UV INSTALLATIONS

The reached maturity of the chemistry in the field of inks and varnishes favors the dissemination among the printers of the LED-UV printing technology. For this purpose, we have created a new business unit for the sale and installation of LED-UV systems within our organization. We offer the possibility of retrofitting any offset machine thanks to our Workshop and our skilled engineers.

LED-UV ADVANTAGES

- no heat transmitted to the material to be printed

- perfect register also on heat-sensitive materials

- increase in the life of LED-UV lamps compared to traditional lamps

- strong savings on maintenance costs

- immediate switching on and off, no need for heating times like traditional mercury lamps (soon forbidden!) UV - HUV - ITUV - LED-UV

- possibility to set the LED-UV on according to the print format avoiding cleaning due to the polymerization of the ink in the periphery of the printing cylinder

- dry sheet and immediately ready for subsequent processing

- no ozone and UVC radiation, it improves the work environment and does not rust the machines

- strong energy savings e

- asy installation

- perfect and constant polymerization for the entire width up to the last day of life of the lamp (traditional mercury lamps (soon forbidden!) UV - HUV - ITUV - LED-UV are also a problem for this aspect)

On the photo comparison between traditional print on the left and print leduv on the right

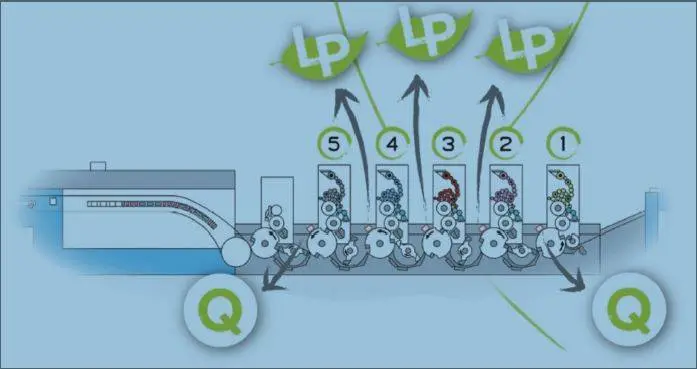

Q-LED High-Power Modular | High power module (20-25W) suitable for the polymerization of inks at high speeds, its main characteristic is the ability to radiate considerable power in the absence of heat. Ideal lamp for final curing |  |

| LP-LED Medium-Power Modular | Medium power module (8-12W) suitable for the prepolymerization of high speed inks or for complete polymerization at low speeds. More compact emission window than Q modules, it is ideal as an interdeck on offset printing machines. |  |

| M-LED High-Power Modular | High power module suitable for the High Curing, to fix high percentage of varnishing | M |

Control system that can be interfaced with most printing machines | Allows you to manage the operation and the power emitted by the various sectors of the lamp based on the profile of the ink fountain of the machine and the print area concerned |  |

| The ability to support the customer and fully understand his needs are one of the most important aspects of the company's offer, able to offer tailor-made solutions; the experience and expertise of the technical personnel of both companies in the field of retrofit of LED-UV systems, represent the best guarantees for those who intend to approach this novelty . |  |

| 4.0 Industry without changing machine | From the Camporese / PrintabLED value proposal, printers can take advantage of innovating their company with an Industry 4.0 approach, moving to UV-LED printing without having to replace their machine and with relatively modest investments | 4.0 Industry |

No need to change the original parts and system of your offset machines | Technological updating operations are rapid and guarantee immediate advantages in economic terms, durability and flexibility, thanks to customized ad hoc systems. based on the specific needs of individual customers. Thanks to the new "GREEN" technology (without mercury and ozone created instead by UV - HUV - ITUV - LED-UV) having to install suction systems It is not necessary to replace the urethane grippers with the steel ones in the cylinders! |  |

The Number Plate Power is one of the most important evaluation criteria of a LED-UV system

Unparalleled LED-UV performance thanks to our patents

In particular, it is useful for customers to ask the supplier to specify the Installed Power of the system (or Targa Power) as it is a fundamental element of electricity consumption.

This must include the entire system, including the cooling system!

References

Many successful installations. Multinational companies of printing industries, graphic industries, artisan companies with a fleet of 2 to 10 colors with or without varnishing unit use the retrofit system proposed by Camporese.

Between 2017 and 2021 more than 60 LED-UV systems were installed by Camporese on the following machines:

- Heidelberg CD102-6LX, CD102-5, XL105-5LX, XL105-6LX, XL75-5LX; SM102-10P; SM52-4

- KBA Rapida 145-6L, Rapida 105-6L

- KBA Mailänder 280;

- Manroland R200; Manroland R500;

- Komori L529.

M. Cavicchioli Production Manager Nava Press Milan with printer

The Number Plate Power is one of the most important evaluation criteria of a LED-UV system

Unparalleled LED-UV performance thanks to our patents

In particular, it is useful for customers to ask the supplier to specify the Installed Power of the system (or Targa Power) as it is a fundamental element of electricity consumption.

This must include the entire system, including the cooling system!

REFERENCES

Many successful installations. Multinational companies of printing industries, graphic industries, artisan companies with a fleet of 2 to 10 colors with or without varnishing unit use the retrofit system proposed by Camporese.

Between 2017 and 2021 more than 60 LED-UV systems were installed by Camporese on the following machines:

- Heidelberg CD102-6LX, CD102-5, XL105-5LX, XL105-6LX, XL75-5LX; SM102-10P; SM52-4

- KBA Rapida 145-6L, Rapida 105-6L

- KBA Mailänder 280;

- Manroland R200; Manroland R500;

- Komori L529.

M. Cavicchioli Production Manager Nava Press Milan with printer

Established reality for the printing of labels, packaging and shoppers, for over 40 years it puts expertise and passion at the disposal of its customers. Innovative facility of 3,700 square meters in Asti, to provide the largest number of services in the same place to optimize work cycles. Mauro and Riccardo Piano are at the helm of the company, and some questions have been asked about the LED-UV technology just installed on their offset printing machine.

Why did you chose to convert your machine from conventional to LED-UV?

The first idea was to change the printing machine, taking a more suitable one for paper converting jobs with coater, long exit and UV driers. After investigating the case I considered the current Heidelberg CD102-5 machines a valid "retrofit" alternative with the LED-UV dryers.

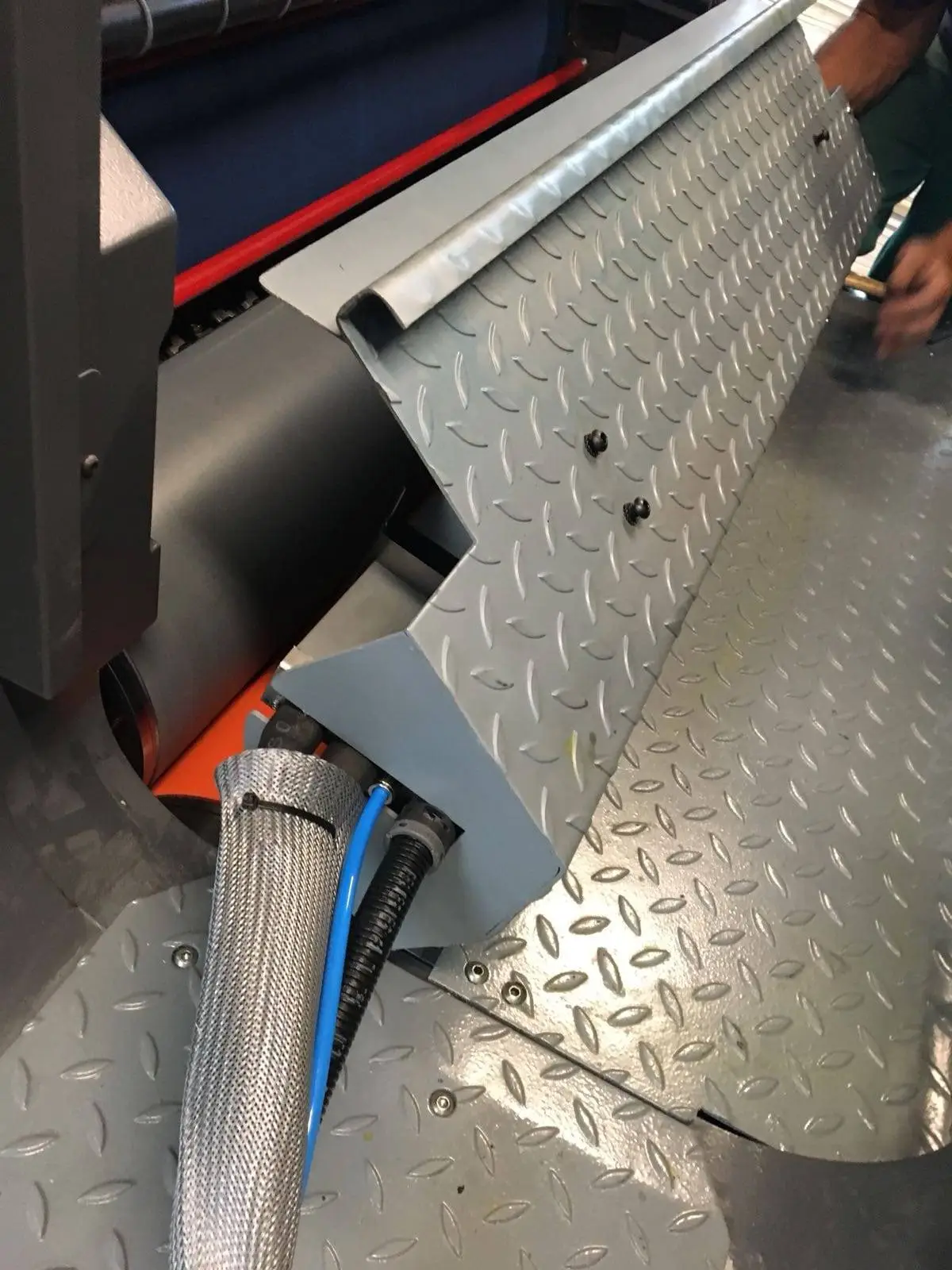

(in the photo, one of the modules used for the test)

Book a LED-UV demo directly on your machine

We guarantee the absence of pollution from the chemistry of your machine, including blankets and rollers that will not be compromised in any way! Making a demo in about half a day and seeing the first dried sheet come out with our LED UV lamps directly on our customers' machines with us is possible!

Possibility of financing and rental

For a financing proposal or an operational rental, contact us!

Request a visit from one of our technicians

The Camporese staff will guarantee customers the necessary technical and commercial advices:

consultancy and technical support directly from the Italian No. 1 assembler and specialist

installation and after sales support

Call Now : Tel. +39 049 767166